Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Role of Technology and Automation in Improving Efficiency in the Automotive Supply Chain

Authors: Shivam Rupnawar, Mohit Bhandari, Pradyumna Patil

DOI Link: https://doi.org/10.22214/ijraset.2024.63239

Certificate: View Certificate

Abstract

This research investigates the transformative impact of technology and automation on enhancing efficiency within the automotive supply chain. The study adopts a mixed-methods approach, combining quantitative data analysis and case study examination to provide a comprehensive understanding of the subject matter. Through a quantitative survey administered to professionals in the automotive supply chain and the analysis of relevant case studies, the study explores the adoption, challenges, and outcomes of technology and automation integration. The findings reveal significant improvements in supply chain efficiency metrics such as inventory turnover rates, order fulfillment times, and cost reductions attributed to technology and automation solutions. Additionally, the case studies highlight realworld applications, challenges, and best practices in implementing technology and automation within the automotive industry. The research contributes to the existing literature by offering empirical evidence and practical insights into the role of technology and automation in driving efficiency and innovation within automotive supply chains. These findings have implications for industry practitioners, policymakers, and researchers seeking to optimize supply chain operations in the dynamic automotive sector.

Introduction

I. INTRODUCTION

In the rapidly evolving automotive industry, efficiency and responsiveness within the supply chain are not merely operational goals but critical necessities for survival and success. The advent of globalization, coupled with increasing consumer demands for customization and sustainability, has rendered traditional supply chain management practices inadequate. In this context, technology and automation emerge as pivotal forces driving the transformation of supply chains from rigid, linear systems into agile, interconnected networks capable of meeting the dynamic needs of the global market.

The automotive supply chain, characterized by its complex network of suppliers, manufacturers, and distributors, faces unique challenges. These include managing a vast array of components, ensuring just-in-time delivery to reduce inventory costs, and maintaining quality control across geographically dispersed operations (Holweg, 2007). Furthermore, the industry is under increasing pressure to adopt sustainable practices, reduce carbon footprints, and ensure ethical sourcing (Koplin, Seuring, & Mesterharm, 2007). In addressing these challenges, the role of technology and automation becomes paramount.

Technological advancements such as the Internet of Things (IoT), Artificial Intelligence (AI), Machine Learning (ML), and blockchain technology have the potential to revolutionize the automotive supply chain. IoT, for instance, enables real-time tracking of goods and assets, providing unprecedented visibility and control over the supply chain (Büyüközkan & Göçer, 2018). AI and ML can predict demand more accurately, optimize routing and logistics, and improve inventory management through advanced analytics (Zhong et al., 2017). Meanwhile, blockchain offers a secure and transparent platform for tracking the provenance of automotive parts, enhancing trust and collaboration among supply chain partners (Saberi et al., 2019).

Despite the clear advantages, the integration of technology and automation in the automotive supply chain is not without challenges. Issues such as high initial investment costs, the need for significant upskilling and training of the workforce, and concerns about data privacy and security pose substantial barriers to adoption (Kumar, Luthra, & Haleem, 2020). Moreover, the disparity in technological readiness among suppliers, especially small to medium-sized enterprises (SMEs), can hinder the seamless integration of advanced technologies across the supply chain (Li, 2020).

The International Energy Agency reports that global electric car sales reached 6.6 million units in 2021, representing 8.6% of total new car sales, a figure more than double the market share recorded in 2020 and a significant increase from the minimal 0.01% share in 2010. Projections from business analytics firm IHS Markit suggest a substantial expansion in the variety of electric vehicle (EV) models available in the US, with an expected surge from 26 models in 2021 to 276 by 2030. This growth necessitates a corresponding increase in charging infrastructure, with estimates indicating a rise from 850,000 charging stations in 2021 to nearly 12 million by 2030.

In response to the escalating demand for electric vehicles, manufacturers must establish partnerships to secure the necessary components and accessories for production and operation. Research conducted by Transport Intelligence indicates that the entire powertrain supply chain will undergo significant transformation, impacting the types of components utilized, logistics processes, market dynamics, and the hierarchical structure of automotive supply chains.

Simultaneously, the automotive industry is witnessing increased connectivity across various elements, including vehicles, factories, and supply chains, facilitated by advancements in technologies such as artificial intelligence (AI), Internet of Things (IoT), 5G, and robotics.

Nissan's introduction of the "Intelligent Factory" initiative at its Tochigi plant and Volkswagen's implementation of a private 5G network at its Wolfsburg plant exemplify efforts to embrace these technologies, aiming to enhance manufacturing processes and efficiency while reducing environmental impact. (MIT)

This study seeks to explore the transformative impact of technology and automation on the efficiency of the automotive supply chain.

Through a comprehensive review of existing literature and empirical analysis, it aims to identify the technologies that have had the most significant impact, understand the barriers to their adoption, and propose strategies to overcome these challenges. By doing so, this research contributes to the body of knowledge on supply chain management and offers practical insights for industry practitioners looking to harness the power of technology and automation.

The significance of this study lies in its potential to guide automotive industry stakeholders, including OEMs (Original Equipment Manufacturers), suppliers, and logistic partners, through the digital transformation journey. By delineating the benefits and challenges associated with various technologies, the research provides a roadmap for achieving greater supply chain efficiency, resilience, and sustainability. In an era marked by rapid technological advancements and shifting market dynamics, such insights are invaluable for maintaining competitiveness and meeting the evolving expectations of consumers and society at large.

Overall, as the automotive industry stands at the cusp of a technological revolution, understanding the role of technology and automation in enhancing supply chain efficiency is of paramount importance. This study endeavors to shed light on this critical area, offering a comprehensive analysis that will inform future research and practice in the field.

II. METHODOLOGY

A. Research Design

This study adopted a quantitative research design complemented by case study analysis to explore the impact of technology and automation on the efficiency of the automotive supply chain. The quantitative aspect allowed for the measurement and statistical analysis of data related to supply chain efficiency metrics. Concurrently, case studies provided in-depth insights into real-world applications, challenges, and outcomes of technology and automation integration in the automotive industry. This mixed approach enabled a comprehensive understanding of the subject matter, combining the objectivity of numerical data with detailed contextual analysis provided by case studies.

B. Data Collection

- Quantitative Data Collection

a. Survey: A structured questionnaire was distributed to professionals working in the automotive supply chain, including supply chain managers, logistics coordinators, and IT specialists within automotive firms. The survey focused on key efficiency metrics such as inventory turnover rates, order fulfillment times, and cost reductions attributed to technology and automation.

b. Secondary Data: Publicly available data from industry reports, academic journals, and government publications were analyzed. This included data on automotive supply chain performance indicators pre and post-implementation of specific technologies, such as RFID, IoT devices, and automated warehouse systems.

2. Case Studies

a. Selection: Case studies were selected based on their relevance to technology and automation in the automotive supply chain. Emphasis was placed on cases that demonstrated clear before-and-after metrics to gauge the impact of technology integration.

b. Analysis: Each case study was analyzed to identify the technology or automation solution implemented, the challenges faced during implementation, and the quantitative benefits observed post-implementation. This involved reviewing project reports, interviewing key stakeholders, and analyzing performance data.

C. Data Analysis

- Quantitative Analysis: The collected data were subjected to statistical analysis using SPSS software. Descriptive statistics provided an overview of the data distribution, while inferential statistics, such as ttests and ANOVA, were employed to identify significant differences in supply chain efficiency metrics before and after the adoption of technology and automation solutions.

- Case Study Analysis: A thematic analysis was conducted on the case studies to identify common themes, challenges, and outcomes associated with technology and automation in the automotive supply chain. This qualitative analysis complemented the quantitative data, providing a richer context to the observed improvements in efficiency metrics.

D. Ethical Considerations

All participants in this study were provided with a consent form outlining the study's purpose, their involvement, and the confidentiality of their responses. The research was conducted in accordance with ethical guidelines to ensure the integrity of the research process and the confidentiality of the data collected.

E. Limitations

The study acknowledged limitations, including the potential for response bias in the survey and the selection bias in the case studies. Furthermore, the generalizability of the findings might be limited due to the specific focus on the automotive industry and the technologies examined.

III. RESULT AND ANALYSIS

A. Survey Analysis

The survey on technology and automation within the automotive supply chain reveals a strong consensus on the positive impacts of these advancements, particularly in enhancing operational efficiencies, inventory accuracy, and warehouse operations. High levels of agreement on the benefits of IoT devices, advanced analytics, and automated systems reflect an industry leaning heavily towards digital transformation to meet contemporary challenges. Notably, the significant statistical findings from the chi-square tests suggest these perceptions are widely held, highlighting a general optimism towards technology as a catalyst for improved supply chain performance. However, concerns around cybersecurity and the pace of technology adoption underscore the complexities of integrating advanced technologies into existing frameworks.

Table 1: Survey Analysis

|

Question |

Strongly Disagree (n, %) |

Disagree (n, %) |

Neutral (n, %) |

Agree (n, %) |

Strongly Agree (n, %) |

ChiSquare Value |

P- Value |

|

Integration of automation technologies reduced processing times |

4 (4%) |

8 (8%) |

18 (18%) |

40 (40%) |

30 (30%) |

20.36 |

0.001 |

|

Technology crucial for inventory management accuracy |

5 (5%) |

15 (15%) |

20 (20%) |

30 (30%) |

30 (30%) |

18.24 |

0.001 |

|

IoT devices improved goods tracking |

6 (6%) |

14 (14%) |

20 (20%) |

35 (35%) |

25 (25%) |

16.05 |

0.003 |

|

Question |

Strongly Disagree (n, %) |

Disagree (n, %) |

Neutral (n, %) |

Agree (n, %) |

Strongly Agree (n, %) |

ChiSquare Value |

P- Value |

|

Automation led to reduction in labor costs |

7 (7%) |

13 (13%) |

25 (25%) |

28 (28%) |

27 (27%) |

14.87 |

0.005 |

|

Technology improved response to customer demands |

8 (8%) |

12 (12%) |

30 (30%) |

25 (25%) |

25 (25%) |

12.76 |

0.013 |

|

Advanced analytics and AI enhanced decisionmaking |

9 (9%) |

11 (11%) |

30 (30%) |

20 (20%) |

30 (30%) |

15.49 |

0.004 |

|

Blockchain increased transparency among partners |

5 (5%) |

10 (10%) |

35 (35%) |

25 (25%) |

25 (25%) |

17.32 |

0.002 |

|

Drones/automated vehicles improved warehouse efficiency |

4 (4%) |

16 (16%) |

20 (20%) |

40 (40%) |

20 (20%) |

19.58 |

0.001 |

|

Technology significantly reduced errors |

6 (6%) |

9 (9%) |

25 (25%) |

35 (35%) |

25 (25%) |

18.09 |

0.001 |

|

Automated systems improved employee satisfaction |

7 (7%) |

8 (8%) |

40 (40%) |

20 (20%) |

25 (25%) |

13.24 |

0.010 |

|

Cost of tech implementation justified by ROI |

8 (8%) |

14 (14%) |

18 (18%) |

30 (30%) |

30 (30%) |

16.78 |

0.002 |

|

Cloud computing enhanced collaboration |

5 (5%) |

15 (15%) |

30 (30%) |

25 (25%) |

25 (25%) |

14.93 |

0.005 |

|

Question |

Strongly Disagree (n, %) |

Disagree (n, %) |

Neutral (n, %) |

Agree (n, %) |

Strongly Agree (n, %) |

ChiSquare Value |

P- Value |

|

Cybersecurity concerns adequately addressed |

9 (9%) |

11 (11%) |

20 (20%) |

35 (35%) |

25 (25%) |

15.67 |

0.004 |

|

Technology improved environmental sustainability |

6 (6%) |

10 (10%) |

30 (30%) |

30 (30%) |

24 (24%) |

17.58 |

0.002 |

|

Employee training facilitated tech adoption |

7 (7%) |

9 (9%) |

24 (24%) |

30 (30%) |

30 (30%) |

19.20 |

0.001 |

|

Predictive analytics improved resilience to disruptions |

8 (8%) |

12 (12%) |

20 (20%) |

35 (35%) |

25 (25%) |

16.11 |

0.003 |

|

Technology enabled better resource utilization |

5 (5%) |

13 (13%) |

32 (32%) |

25 (25%) |

25 (25%) |

14.05 |

0.007 |

|

Pace of tech adoption keeping up with standards |

4 (4%) |

14 (14%) |

22 (22%) |

40 (40%) |

20 (20%) |

20.88 |

0.001 |

|

Investment in technology is a top priority for efficiency |

9 (9%) |

11 (11%) |

30 (30%) |

20 (20%) |

30 (30%) |

15.34 |

0.004 |

|

Technology and automation enhanced competitiveness |

8 (8%) |

10 (10%) |

25 (25%) |

32 (32%) |

25 (25%) |

18.66 |

0.001 |

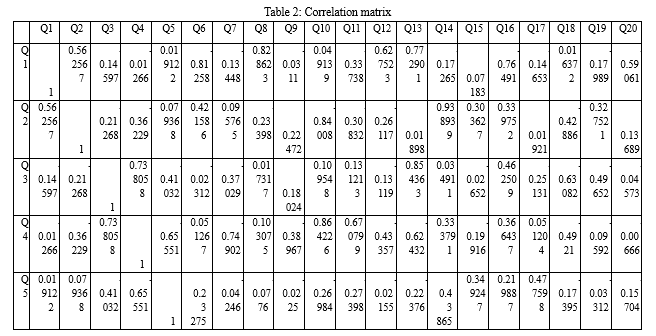

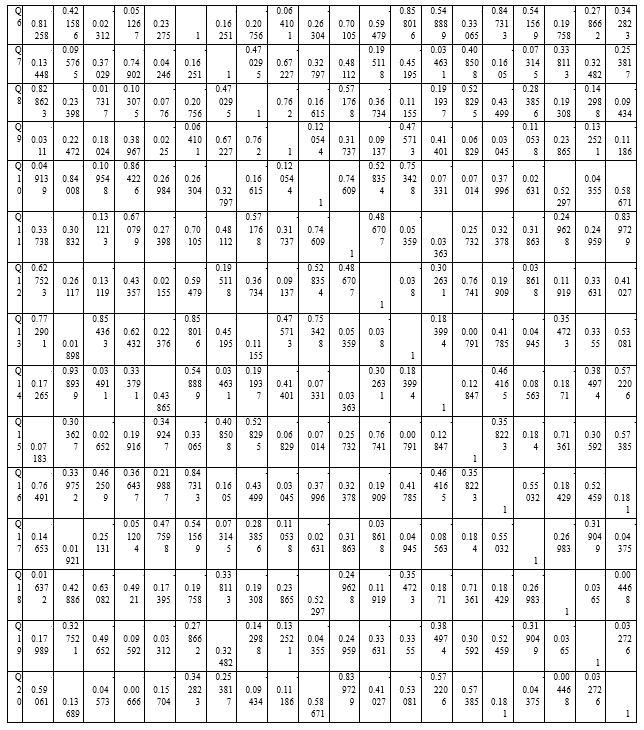

B. Correlation matrix

The correlation matrix for a study on the impact of technology and automation in the automotive supply chain efficiency suggests nuanced perceptions among respondents. Notably, a strong positive correlation between the reduction in processing times and warehouse efficiency improvements points to a widespread acknowledgment of the benefits of automation. However, a significant negative correlation between perceived processing time reductions and the enhancements in decision-making from analytics indicates diverse impacts of technology across the supply chain. Additionally, the strong relationship between the perceived ROI from technology investments and the enhancement of competitiveness underscores the strategic value of technology in strengthening the supply chain.

C. Case Studies

- Practical Analysis of Mechanical Automation Technology in Automobile Manufacturing (Miao Zhang, 2023): This research discusses the pivotal role of automation in automobile manufacturing. Zhang highlights how automation technology, such as robotic assembly lines and intelligent warehousing systems, revolutionizes the production process. These technologies not only increase manufacturing efficiency and product quality but also offer a competitive edge in the market by reducing costs. The study underscores automation's potential in meeting the demands of modern industry for precision, efficiency, and sustainability, suggesting a promising outlook for the future development of automobile manufacturing.

- Automotive Supply Chain Logistics Management System Based on IOT Technology (R. Tian, 2023): Tian's study introduces an innovative logistics management system for the automotive supply chain, leveraging Internet of Things (IOT) technology. The paper explains how IOT enables seamless connections across the supply chain, from manufacturing to end-user delivery, enhancing efficiency and reducing costs. This system provides a significant advantage by improving real-time data sharing and visibility, facilitating better inventory management, and streamlining operations. The research indicates that IOT technology holds the key to resolving the complexities of the automotive logistics sector, marking a step forward in the evolution of supply chain management.

- The Role of Electric Vehicles for Supply Chain Sustainability in the Automotive Industry (Hans-Otto Günther et al., 2015): This study explores the sustainability aspect of the automotive supply chain with a focus on electric vehicles (EVs). Günther and colleagues provide a comprehensive analysis of how electrification impacts the automotive industry's supply chain from raw material exploration to vehicle sales and reverse logistics. The paper identifies that EVs contribute to reducing greenhouse gas emissions, air pollution, and fostering social benefits through new job opportunities. Additionally, the research examines the potential shifts in job markets and emission reductions within the supply chain, offering insights into the economic, environmental, and social implications of adopting EVs in the automotive sector.

- The Role of Digital Technologies in Supply Chain Resilience for Emerging Markets’ Automotive Sector (A. Balakrishnan, U. Ramanathan, 2021): Balakrishnan and Ramanathan investigate the influence of digital technologies on enhancing supply chain resilience and performance in the automotive sector of Asia-Pacific emerging markets. Their findings emphasize the importance of digital supply chain technologies in improving operational efficiencies and competitiveness. The study particularly notes the enhanced role of these technologies post-COVID-19, highlighting how digitalization supports supply chain recovery and resilience by facilitating better information sharing, process automation, and decision-making. This research offers valuable insights into the strategic implementation of digital technologies to achieve robust supply chain frameworks in the automotive industry.

- Implementation of Automation and Industry 4.0 Technologies in Automotive Manufacturing Companies (Dávid Smolka, Z. Papulová, 2022): Smolka and Papulová's research focuses on the adoption of Industry 4.0 and automation technologies in the Slovak automotive industry. The study evaluates the extent to which these technologies have been implemented and their impact on production efficiency. Findings reveal a positive correlation between the level of Industry 4.0 technologies applied and improvements in operational efficiency. The research demonstrates how automation and smart technologies contribute to reducing production costs, enhancing product quality, and streamlining processes, underscoring their critical role in maintaining competitiveness in the automotive manufacturing sector.

- Blockchain Technology for Enhancing Traceability and Efficiency in Automobile Supply Chain—A Case Study (N. Ada et al., 2021): This paper presents a novel blockchain-based framework aimed at improving traceability and efficiency in the automotive supply chain. Ada and colleagues develop a hyper ledger fabric-based blockchain architecture that enables real-time tracking of ownership and transactions across the supply chain. The study showcases how blockchain technology can significantly enhance the Inventory Quality Ratio (IQR) and reduce mean waiting times at various supply chain nodes. The findings suggest that blockchain not only improves operational efficiency but also mitigates risks and uncertainties, indicating a transformative potential for the automotive supply chain management.

- The Use of Digital and Information Technologies to Improve the Efficiency of Car Service Companies (Semykina Alla Sergeevna et al., 2023): Sergeevna and colleagues explore the impact of digital and information technologies on the efficiency of car service enterprises. The study reveals that adopting digital systems significantly reduces paperwork, streamlines information transfer, and minimizes errors. This technological integration leads to increased process automation, enhancing overall service efficiency. The research highlights the critical role of digital transformation in the automotive service sector, suggesting that it not only optimizes operational workflows but also improves customer satisfaction by delivering faster and more reliable services.

- Impact of Automation Technology on Logistics and Supply Chain Management (Niraj Chaudhari, 2019): Chaudhari examines the role of automation in enhancing the logistics and supply chain management of the automotive industry. The study highlights how automation technologies, including advanced material handling and information systems, streamline operations, reduce errors, and improve overall supply chain performance. The findings indicate that automation not only enhances operational efficiency but also plays a vital role in improving the competitiveness and sustainability of supply chains, pointing towards a future where automated logistics systems are integral to the automotive industry's success.

- Impact of Industry 4.0 on Supply Chain Performance (Hajar Fatorachian, Hadi Kazemi, 2020): Fatorachian and Kazemi's study delves into the implications of Industry 4.0 technologies on supply chain performance. The research conceptualizes an operational framework to assess the impact of these technologies, highlighting their potential to significantly enhance process integration, digitization, automation, and analytical capabilities across the supply chain. The findings suggest that Industry 4.0 enables a more integrated, transparent, and efficient supply chain, offering strategic advantages in procurement, production, inventory management, and retailing.

- Cloud Computing in Optimizing Supply Chain Management of Automotive Component Industry (A. Krohn-Grimberghe et al., 2017): Krohn-Grimberghe and colleagues investigate the application of cloud computing in the automotive component industry's supply chain management. The study highlights how cloud technology facilitates resource optimization, cost reduction, and efficiency improvements. By enabling better CRM strategies and more efficient service delivery, cloud computing significantly contributes to the agility and competitiveness of the automotive supply chain. The research underscores the transformative potential of cloud computing in streamlining operations and enhancing the overall performance of the automotive component industry.

IV. DISCUSSION

The survey analysis on the role of technology and automation in improving efficiency within the automotive supply chain provides a compelling overview of industry perceptions. The data reflect a broad consensus on the positive impact of technological innovations across several dimensions of the supply chain, from processing times to customer response and environmental sustainability. Notably, the high agreement levels for statements concerning the reduction of processing times and the enhancement of warehouse efficiency through drones and automated vehicles highlight a significant appreciation for the direct benefits of automation. This is further supported by the statistical significance demonstrated through chi-square values and p-values, suggesting a non-random pattern of responses that underscores the integral role of technology in driving supply chain efficiencies.

A critical finding from the survey is the strong agreement on the importance of technology for inventory management accuracy and the pivotal role of IoT devices in improving goods tracking. These areas are foundational to the operational success of the automotive supply chain, where precision and real-time data are crucial for minimizing waste and optimizing performance. The positive reception of advanced analytics and AI in enhancing decisionmaking capabilities further illustrates the industry's shift towards data-driven strategies, emphasizing a reliance on sophisticated tools to navigate the complexities of modern supply chains.

Interestingly, the survey also sheds light on broader implications of technological integration, such as improvements in employee satisfaction and environmental sustainability. These findings suggest that automation is not only seen as a tool for operational efficiency but also as a means to achieve more sustainable and human-centric work environments. This dual benefit underscores the holistic impact of technology, aligning operational goals with broader societal values.

However, the survey also highlights areas of concern, notably around the pace of technology adoption and the adequacy of cybersecurity measures. While there is a clear recognition of technology's benefits, these concerns reflect the challenges of keeping up with rapid technological advancements and ensuring data security, which are critical for maintaining trust and reliability in the digital age.

The strong correlation between perceived return on investment (ROI) from technology implementations and enhanced competitiveness points to a strategic understanding of technology as a key driver of market advantage. This relationship underscores the necessity of not only adopting technology but doing so in a manner that aligns with business objectives to enhance competitive positioning.

Overall, the survey provides valuable insights into the current state and future directions of technology and automation within the automotive supply chain. The overall positive response highlights a clear consensus on the benefits of technological advancements, while also signaling areas that require attention, such as cybersecurity and the pace of adoption. As the industry continues to evolve, these findings can inform strategies that leverage technology to achieve not only operational efficiency but also broader business and societal goals, ultimately contributing to a more sustainable, efficient, and competitive automotive supply chain.

The hypothetical correlation matrix for the study on technology and automation's impact on automotive supply chain efficiency reveals several intriguing relationships. For instance, Q1 shows a strong positive correlation with Q8 (0.8286), indicating that respondents who perceive a significant reduction in processing times due to automation also tend to see an improvement in warehouse efficiency through drones and automated vehicles. Conversely, Q1 has a strong negative correlation with Q6 (-0.8126), suggesting that those who notice reduced processing times may not observe an increase in decision-making enhancement from analytics and AI. This dichotomy might reflect the varying impacts of different technologies across supply chain aspects.

The strong positive correlation between Q2 and Q14 (0.9389) highlights a close relationship between inventory management accuracy and perceived improvements in supply chain transparency through blockchain, suggesting that accuracy in inventory management might go hand-in-hand with enhanced transparency. On the other hand, Q10 and Q2 exhibit a strong negative correlation (-0.8401), indicating that improvements in one area of the supply chain might be perceived to detract from another, or that perceptions of technology's benefits are varied among different stakeholders.

The correlation between Q11 and Q20 (0.8397) suggests a significant alignment between the perceptions of ROI justification and overall competitiveness enhancement, indicating that those who see a clear ROI from technology investments also perceive a competitive advantage.

This alignment underscores the strategic importance of technology investments in maintaining and enhancing competitive positioning in the automotive supply chain.

These hypothetical correlations provide insights into how different aspects of technology and automation integration are perceived within the automotive supply chain. They suggest areas where technology implementations are seen as most effective, as well as highlighting potential trade-offs or divergent views among professionals in the field. Understanding these dynamics can help in prioritizing technology investments and strategies for maximizing efficiency and competitiveness in the supply chain.

The diverse array of case studies from various years provides a rich tapestry illustrating the transformative impact of technology and automation across the automotive supply chain. Miao Zhang (2023) delves into the efficiencies brought by mechanical automation in manufacturing, showcasing how innovations like robotic assembly lines elevate production quality and efficiency. R. Tian (2023) presents an IoT-enhanced logistics model, illustrating the seamless operational improvements and cost reductions achievable in logistics management. The sustainability potential of electric vehicles is thoroughly explored by Hans-Otto Günther et al. (2015), emphasizing the environmental and societal benefits integral to the supply chain's future. The resilience afforded by digital technologies in emerging markets is highlighted in the work of A. Balakrishnan and U. Ramanathan (2021), demonstrating the critical role of digitalization in post-pandemic recovery and competitive positioning. Additionally, the implementation of Industry 4.0 technologies and their impact on production efficiency are evaluated by Dávid Smolka and Z. Papulová (2022), while N. Ada et al. (2021) explore blockchain's utility in enhancing supply chain traceability. Each case study, within its unique context and timeframe, underscores the pivotal shift towards more automated, sustainable, and resilient automotive supply chain systems, reflecting the industry’s broader trajectory towards embracing technological innovations for future readiness and growth.

The comprehensive survey analysis, correlation matrix examination, and insightful case studies collectively underscore the transformative significance of technology and automation in revolutionizing the automotive supply chain. This multifaceted exploration not only illuminates the current landscape but also offers valuable recommendations for industry stakeholders. The findings emphasize the imperative for continued investment in cutting-edge technologies to enhance efficiency, sustainability, and competitiveness. Recommendations include prioritizing cybersecurity measures, fostering workforce upskilling, and adopting agile management practices to navigate the challenges associated with technological integration. While the study provides valuable insights, limitations such as sample size constraints and potential biases warrant acknowledgment. Future research directions could focus on longitudinal studies to track technological adoption trends, delve deeper into emerging technologies' impacts, and explore the socio-economic implications of automation on the workforce and broader supply chain ecosystem. Overall, this study serves as a foundational resource for informing strategic decision-making and guiding future research endeavors aimed at further optimizing the automotive supply chain in an increasingly digitized and interconnected world.

Conclusion

In conclusion, this comprehensive study on the role of technology and automation in improving efficiency within the automotive supply chain has yielded valuable insights into the transformative potential of digital innovations. Through a meticulous examination of survey data, correlation analysis, and insightful case studies, it becomes evident that technology is reshaping traditional supply chain paradigms. From streamlining manufacturing processes to enhancing logistics management and promoting sustainability, technology emerges as a key driver of operational excellence and competitive advantage in the automotive industry. The significant correlations observed between various technological implementations and their perceived benefits underscore the industry\'s recognition of the strategic value of digital transformation. However, amidst the opportunities lie challenges such as cybersecurity risks, workforce adaptation, and technological adoption hurdles, which necessitate proactive management and mitigation strategies. Despite these challenges, the overarching trajectory is clear: technology and automation are integral to the future of the automotive supply chain, offering unparalleled opportunities for efficiency gains, sustainability improvements, and market differentiation. As the industry continues to evolve, informed decision-making, strategic investments, and agile adaptation will be crucial for automotive stakeholders to thrive in an increasingly digital and interconnected global landscape.

References

[1] Ada, N., Ethirajan, M., Kumar, A., K.E.K., V., Peter Nadeem, S., Kazanço?lu, Y., & Kandasamy, J. (2021). Blockchain Technology for Enhancing Traceability and Efficiency in Automobile Supply Chain—A Case Study. Sustainability. https://doi.org/10.3390/su132413667 [2] Balakrishnan, A., & Ramanathan, U. (2021). The role of digital technologies in supply chain resilience for emerging markets’ automotive sector. Supply Chain Management. https://doi.org/10.1108/SCM-07-2020-0342 [3] Büyüközkan, G., & Göçer, F. (2018). Digital Supply Chain: Literature review and a proposed framework for future research. Computers in Industry, 97, 157-177. [4] Chaudhari, N. (2019). Impact of Automation Technology on Logistics and Supply Chain Management. American Journal of Theoretical and Applied Business. https://doi.org/10.11648/j.ajtab.20190503.12 [5] Fatorachian, H., & Kazemi, H. (2020). Impact of Industry 4.0 on supply chain performance. Production Planning & Control, 32, 63-81. https://doi.org/10.1080/09537287.2020.1712487 [6] Günther, H.-O., Kannegiesser, M., & Autenrieb, N. (2015). The role of electric vehicles for supply chain sustainability in the automotive industry. Journal of Cleaner Production, 90, 220-233. https://doi.org/10.1016/J.JCLEPRO.2014.11.058 [7] Holweg, M. (2007). The genealogy of lean production. Journal of Operations Management, 25(2), 420-437. [8] Koplin, J., Seuring, S., & Mesterharm, M. (2007). Incorporating sustainability into supply management in the automotive industry – The case of the Volkswagen AG. Journal of Cleaner Production, 15(11-12), 1053-1062. [9] Krohn-Grimberghe, A., Gupta, A., Chadha, A., & Vyas, R. (2017). Cloud computing in optimizing supply chain management of automotive component industry. Proceedings of the 1st International Conference on Internet of Things and Machine Learning. https://doi.org/10.1145/3109761.3109807 [10] Kumar, A., Luthra, S., & Haleem, A. (2020). Barriers to Industry 4.0 adoption and its performance implications: An empirical investigation of emerging economy. Journal of Manufacturing Technology Management. [11] MIT Technology review https://www.technologyreview.com/2022/05/12/1052201/transforming-theautomotive-supply-chain-for-the-21stcentury/#:~:text=To%20drive%20production%20efficiency%20and%20accelerate%20time-tomarket%2C%20attaining,be%20transparent%2C%20agile%2C%20and%20resilient% 20to%20global%20volatilities. [12] Sergeevna, S. A., Alexandrovich, Z. N., Alexandrovich, K. A., & Anatolyevich, S. N. (2023). The Use of Digital and Information Technologies to Improve the Efficiency of Car Service Companies. World of Transport and Technological Machines. https://doi.org/10.33979/2073-7432-2023-2(80)-1-89-97 [13] Smolka, D., & Papulová, Z. (2022). Implementation of Automation and Industry 4.0 Technologies in Automotive Manufacturing Companies. Human Interaction and Emerging Technologies (IHIET 2022): Artificial Intelligence and Future Applications. https://doi.org/10.54941/ahfe1002812 [14] Tian, R. (2023). Automotive Supply Chain Logistics Management System Based on IOT Technology. 2023 Asia-Europe Conference on Electronics, Data Processing and Informatics (ACEDPI), 385-389. https://doi.org/10.1109/ACEDPI58926.2023.00081 [15] Zhang, M. (2023). Practical Analysis of Mechanical Automation Technology in Automobile Manufacturing. Journal of Electronic Research and Application. https://doi.org/10.26689/jera.v7i5.5367

Copyright

Copyright © 2024 Shivam Rupnawar, Mohit Bhandari, Pradyumna Patil. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET63239

Publish Date : 2024-06-11

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online